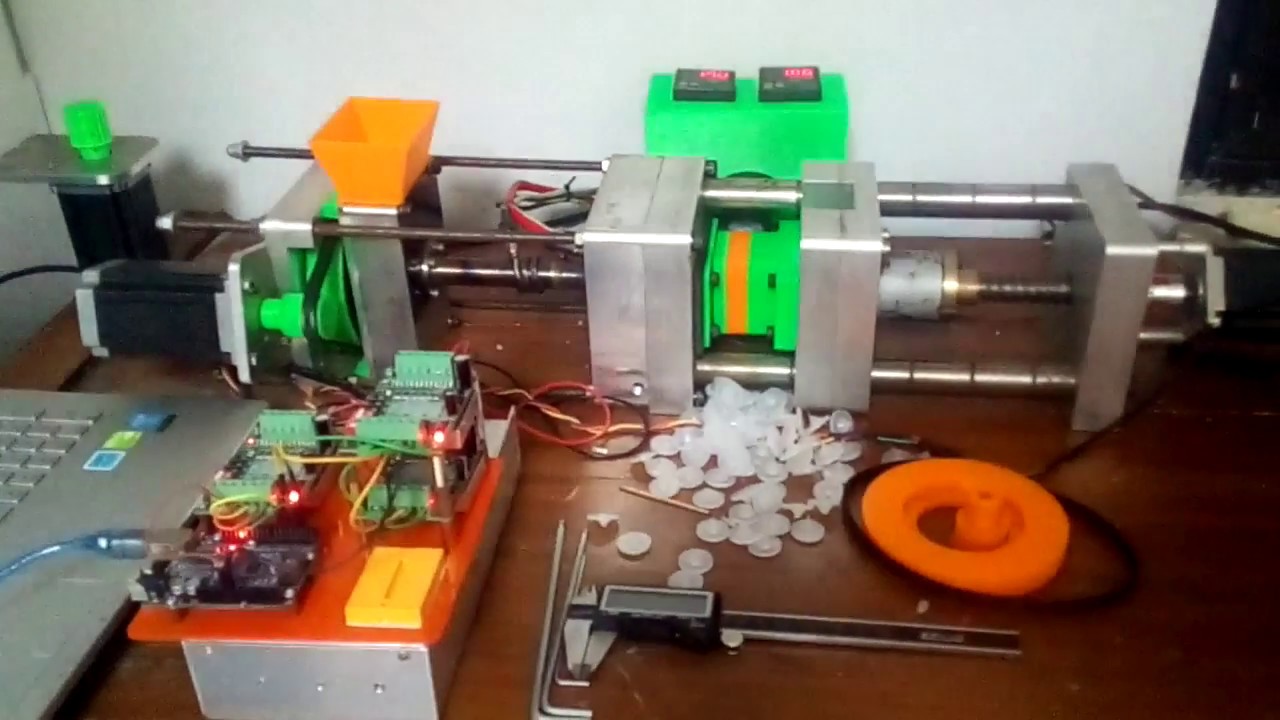

diy injection molding machine arduino

Then after some waiting time the process should be repeated. The silicone mold can be reused.

Step 7 Inject the plastic and let it harden.

. Once you have set up your injection molding machine pour in your plastic pellets. Instructions for building one also are on the Action Box channel. When I first set out to make this all the information readily available was a few pictures of some home made injection machines and a few forums of people discussing making their own very few actually showed what they had done.

I would like to build a small automated injection molding machine and I had some questions about how I would program some of these functions. To start I want it to have a thermostat on the touchscreen as well as a cycle speed control and cycle counter. Stop breadboarding and soldering start making immediately.

C Clamp the mold in place by turning the vise handle clockwise. Anything Can Happen With Hard Work Dedication. In this project we will learn how to make an arduino based diy vending machine.

The molten plastic then gets injected into your mold cavity through the machines injector. Inexpensive homemade molds can be made using an epoxy or urethane resin. Adafruits Circuit Playground is jam-packed with LEDs.

The video on the Action Box channel on Youtube describes the step-by-step process for building the Injekto molding machine with the operative word being simplicity. A temperature controller allows you to set the temperature that you want your molten plastic mixture to be. I work at an injection molding manufacturer.

Generally this machine is common for food-grade trays blisters Abs trays but also for internal cases of household appliances and finishes in the. By its very nature a diy plastic injection molding machine is very versatile and guarantees a very high production flexibility especially if the thickness of the pieces is very thin. Diy Injection Molding Machine Arduino.

You can choose whatever color you want. Then the second motor should run the plastic for a set time press the plastic and stop slowly. After a while I am here thank you for the support I was working on a big project I will show it to you soon enjoy the videoif you like this video please.

Read on to see the best DIY and desktop injection molding machines. You also need a large power supply air compressor water cooling system. After waiting for a set time period the first motor should open the mold while the second motor should retract slightly.

In this video on Buster Beagle 3D Ryan shows how he made a tabletop injection molding machine for around 200. The vacuum is then released. I am interested in the same machine.

I dont understand the point of DIY injection molding. You wont need a machine shop at home and you can even build the mold itself using a DIY CNC machine. Ad Manufacturer Of Pad Printing Ultrasonic Welding Products.

Above is the finished injection molding machine with a partially disassembled moped in the background. Machine is very versatile and flexible. A Place a mold in the machine.

Machines cost in the hundreds of thousands and the aluminum molds can range from 20-120 thousand. Diy desktop small injection molding machine 30g injection video 110v working voltage can be customized contact me whatsapp machine controlled by arduino uno. Hello all Im new to the forum and fairly new to arduino.

Gingerys book secrets of building a plastic injection molding machine. I dont work hands on with the machines but I do the accounting. Https Encrypted Tbn0 Gstatic Com Images Q Tbn And9gcsx6msu6l8wm8vagdjngk I1c N Hri0ummybb7f6uxis Ax Wk Usqp Cau from These pellets are then used to.

Thingiverse is a universe of things. A common PID controller. Mold manufacturing and injection service are so cheap about 2k for mold about 1 per part for reasonably sized and surfaced finish.

The structure of an injection molding machine can be briefly summarized as consisting of an injection unit that sends the melted materials into the mold and a clamping unit that operates the mold. B Make sure the sprue hole on top of the mold lines up exactly with the injection nozzle. Using an off-the-shelf injection molding chamber by buster beagle 3D only a few standoffs and a support bracket needed machining in order to complete the mechanics.

LNS Technologies Model 150A. System June 17 2013 1122am 1. The silicone mold can be reused.

Diy Injection Molding With Double Pnuematic Plastic Injection Molding Injection Moulding Mould Design

Pin On Plastic Injection Molding

Introduction New Version Of Micro Injection Youtube Plastic Injection Molding Plastic Injection Injection Moulding

Tabletop Injection Molding Machine Still A Big Hit Plastic Injection Moulding Machine Plastic Injection Molding Aluminum Molding

Make Your Own Injection Molding Machine Make Plastic Injection Molding Molding Diy Molding

Manual Benchtop Injection Molding Machine Model 150a Pim Shooter Plastic Moulding Plastic Injection Moulding Machine Plastic Injection Molding

13 Build Your Own Injection Molding Machine For Around 200 Youtube Build Your Own Desktop Build Your Own Molding

Bench Mounted Plastic Injection Moulding Machine Plastic Injection Plastic Injection Molding Plastic Moulding

Desktop Injection Molding Machine Get Inquiries 56 Youtube Injection Machine Plastic Injection Molding Plastic Moulding

Plastics Injection Moulding System Plastic Injection Molding Plastic Injection Injection Moulding